Safety Valve Market Share Rising for Manufacturers Offering High-Performance and Reliable Safety Valve Systems

As Per Market Research Future, the Safety Valve Market Share is becoming increasingly competitive, with key players focusing on innovation and customer satisfaction to capture a larger share. The dynamics of market share are influenced by factors such as technological advancements, pricing strategies, and consumer preferences. Leading manufacturers are investing in research and development to introduce new and improved safety valve products that meet the evolving needs of various industries. As the demand for reliable and efficient safety solutions continues to rise, companies that prioritize innovation will likely gain a competitive edge.

The safety valve market has witnessed significant growth in recent years due to increasing industrialization, the expansion of the oil and gas sector, and stringent safety regulations in manufacturing and processing industries. Safety valves play a crucial role in preventing accidents by automatically releasing excess pressure from systems and ensuring operational safety. These valves are widely used across sectors such as oil and gas, chemicals, power generation, and pharmaceuticals, highlighting their importance in modern industrial infrastructure.

Market Drivers and Growth Factors

Rising demand for automated safety systems and strict adherence to regulatory standards are key factors driving the safety valve market. Industries are focusing on improving workplace safety and minimizing downtime caused by overpressure situations. Technological advancements such as smart valves with IoT integration and real-time monitoring capabilities have further boosted the adoption of safety valves. Additionally, the growing infrastructure projects in emerging economies have fueled demand, as industrial plants require reliable pressure relief solutions to maintain operational efficiency.

Technological Advancements in Safety Valves

Modern safety valves are being designed with advanced materials and coatings to enhance corrosion resistance and durability. Smart valves equipped with sensors and automated control systems allow for precise monitoring and predictive maintenance, reducing the risk of unplanned shutdowns. Additionally, compliance with standards such as API and ASME ensures the safety and reliability of these valves in critical industrial applications. Manufacturers are also focusing on compact and high-performance designs suitable for space-constrained installations without compromising safety standards.

Industrial Applications and Demand Trends

The oil and gas industry remains the largest consumer of safety valves due to the high-risk nature of operations. Power generation plants, including nuclear and thermal, also rely heavily on safety valves to maintain pressure limits and protect equipment. Chemical and pharmaceutical industries utilize safety valves in reactors and pressure vessels to ensure process safety. The increasing awareness of workplace safety and environmental regulations is contributing to steady growth in the industrial adoption of safety valves.

Regional Insights

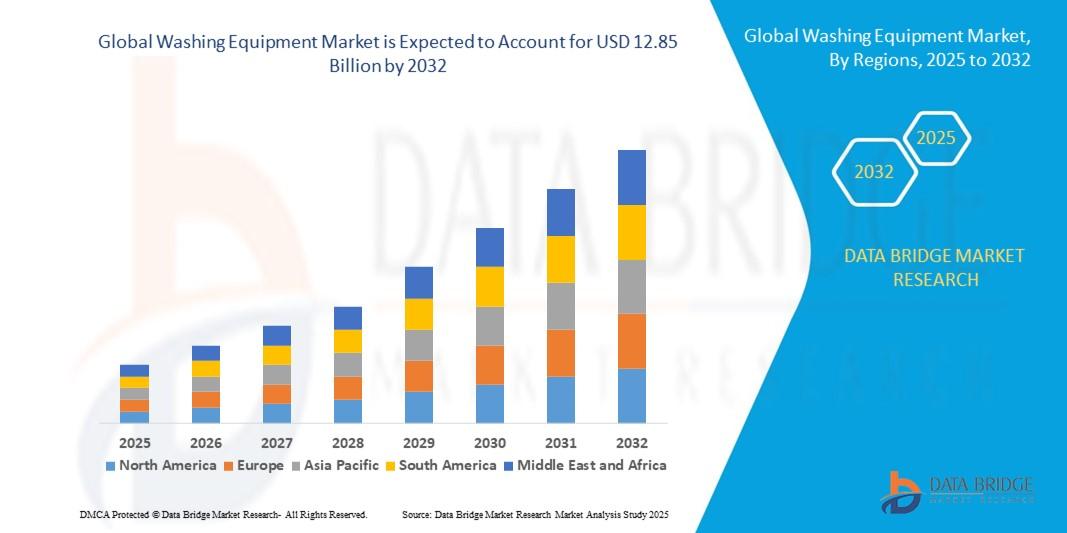

North America and Europe dominate the safety valve market due to strict regulatory frameworks and high adoption of advanced industrial safety solutions. The Asia-Pacific region is emerging as a lucrative market due to rapid industrialization, infrastructure development, and increasing investments in energy and chemical sectors. Countries like China and India are witnessing growing demand for high-quality safety valves to meet the requirements of large-scale industrial projects and expansion of manufacturing facilities.

Competitive Landscape

The safety valve market is highly competitive, with major players focusing on product innovation, strategic partnerships, and regional expansion to maintain market share. Companies are investing in research and development to offer valves with improved safety, efficiency, and integration with automated systems. Product differentiation through advanced features, quality certifications, and customized solutions is a key strategy to gain a competitive edge in the market.

Market Challenges

Despite the growth prospects, the safety valve market faces challenges such as high initial costs of advanced valves, maintenance requirements, and limited awareness among small and medium enterprises regarding the benefits of high-quality safety valves. Additionally, fluctuating raw material prices and supply chain disruptions can impact the production and pricing of safety valves, affecting market stability.

Future Outlook

The global safety valve market is expected to continue its upward trajectory, driven by technological innovation, industrial growth, and increased safety awareness. The integration of IoT and digital monitoring solutions in safety valves is likely to redefine operational safety standards. As industries invest in smart manufacturing and automation, the demand for reliable and compliant safety valves will remain robust, offering significant opportunities for manufacturers and investors.

FAQs

Q1. What industries primarily use safety valves?

Safety valves are widely used in oil and gas, power generation, chemical, and pharmaceutical industries to prevent overpressure situations and ensure operational safety.

Q2. How are technological advancements impacting the safety valve market?

Innovations such as smart valves, IoT integration, and advanced materials have improved valve efficiency, durability, and real-time monitoring capabilities, boosting market demand.

Q3. Which regions offer the highest growth potential for safety valves?

North America and Europe currently lead the market, while Asia-Pacific shows high growth potential due to industrialization, infrastructure development, and increased adoption in emerging economies.

More Trending Reports Industrial Automation Equipment Market Report by Market Research Future